ÖLÇÜ KONTROL

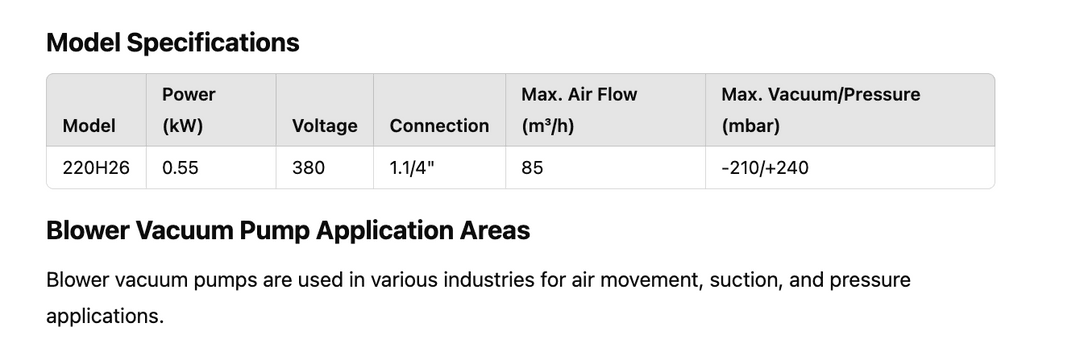

220H26 Double Stage Blower Three Phase (380V) 0.55 kW 85 m³/h

What is a Blower?

A blower is a facility equipment that transfers air in an environment exposed to emission at a high flow rate or low pressure. It operates by rotating a fan using the power received from a motor.

In short, blowers are devices that transport air by blowing it.

Where Are Blowers Used?

Blowers are used in various applications, including:

- Gas flow through sewage systems, process piles, etc.

- Exhausting, aspiration, cooling, ventilation, and air conveyance.

- Wastewater Treatment Plants

- Car Wash Systems

- Paper Cutting Processes

- Bottle Drying

- Jacuzzi Systems

- Post-Printing Drying in Printers

- Fermentation Processes

- Oxygen Supply in Pools

- Heating Systems (Boilers, Furnaces, etc.)

- Vegetable and Fruit Washing

- Pipe Cleaning

- Dust and Particle Transport

How to Select a Blower?

Incorrect blower selection can result in poor performance and unnecessary electricity costs. In this section, we will cover the key considerations for selecting the right blower for industrial applications.

- Determine the location where the blower will be installed.

- Measure the area where it will be used.

- Decide on the direction of the airflow.

- Design an installation plan, including the blower, ducts, equipment, and processes.

- Determine the required airflow values for the application.

- Answer questions regarding the temperature of incoming air, its source, and its entry method.

- Consider the pressure loss in the airflow outside the duct.

Essential Data for Blower Selection

Once all these calculations are made, the most important factors for choosing a blower include:

- Required air flow rate (m³/h)

- Positive pressure the blower needs to overcome (if used for air transfer) (mbar, bar, mSS, etc.)

- Vacuum level required (if used for suction) (-mbar, -bar, etc.)

- Ambient temperature

By answering these questions, you can outline the type of blower you need. For more detailed product analysis, please contact us.