ÖLÇÜ KONTROL

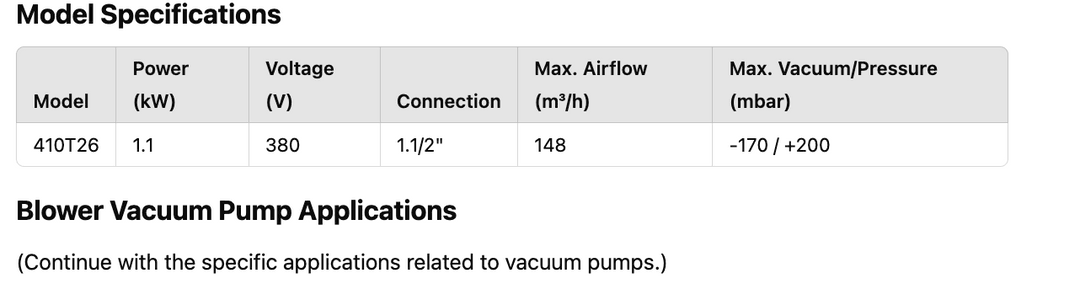

410T26 Single Stage Blower Three Phase (380V) 1.1 kW 148 m³/h

What is a Blower?

What is a Blower?

A blower is an installation equipment that transfers air in high flow or low pressure from an environment affected by emission. It operates by rotating a fan using power from a motor.

In short, blowers are devices that move air by blowing it.

Where are Blowers Used?

Blowers are used in various applications where gas or air needs to be conveyed, exhausted, aspirated, cooled, ventilated, or transported. Some common applications include:

- Sewage systems and process stacks for gas flow

- Exhaust, aspiration, cooling, and ventilation

- Water treatment plants

- Car washing stations

- Paper cutting processes

- Bottle drying systems

- Jacuzzis

- Drying after printing in printers

- Fermentation processes

- Providing oxygen in pools

- Heating systems (e.g., boilers)

- Vegetable and fruit washing

- Pipe cleaning

- Dust and particle transportation

How to Select a Blower?

Choosing the wrong blower can lead to poor performance and unnecessary electricity costs. Here are key steps to selecting the right industrial blower:

- Determine the blower's location.

- Measure the area where it will be used.

- Decide on the direction of airflow.

- Design an installation plan (including the blower, ducts, equipment, and process layout).

- Define the required airflow values for the application area.

- Consider factors such as:

- The temperature of the air entering the blower

- The source and method of air intake

- Pressure loss in the duct system

- After gathering all calculations, focus on these key blower selection parameters:

- Required airflow capacity

- Positive pressure that the blower needs to overcome (mbar, bar, or meters of water column - mSS)

- Vacuum pressure required if used for suction (-mbar, -bar)

- Ambient temperature

By answering these questions, you can determine the type of blower needed for your application. For further product details, please contact us.