KAMPA-M

Kampa Radiator Cleaning Machine Double-Sided Pro-4 Resistance + 30 Kg. Chemical

Kampa Pro-4 Descaling Pumps

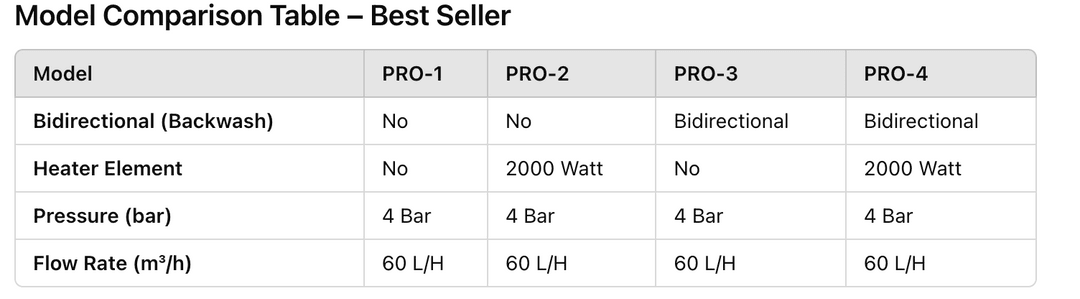

The Pro-4 model is specially designed for chemical cleaning of radiators, pipelines, and large-scale installations, as well as draining and refilling systems. Equipped with cleaning, filling, and draining connections on the machine, it allows effortless and fast cleaning from a single point.

The reverse cleaning feature enables water to flow in two directions through the system. Dual-direction cleaning machines achieve 26% better cleaning efficiency.

The 2000 Watt heating element is protected against dry operation and ensures efficient and safe cleaning.

The machine is constructed from materials resistant to chemicals to ensure long-term, trouble-free operation. The durable plastic body and plastic jet pump motor prevent wear caused by debris or chemicals, maintaining the machine's performance for years.

Power Flushing Technical Specifications

- Model: Pro-4

- Liquid Tank Capacity: 40 Liters

- Pressure: 4 Bar

- Flow Rate: 60 Liters/Minute

- Voltage: 220 Volts

- Heating Element: 2000 Watt

- Motor Power: 600 Watt (0.8 Hp)

- Power Cord: 3 Meters with Plug

- Weight: 19.6 kg

- Dimensions (L x W x H): 35 cm x 45 cm x 75 cm

Entkalkungspumpe Motor

The pump is the most crucial part of radiator cleaning machines, determining the performance and quality of cleaning. With its powerful pump, the machine efficiently cleans closed-circuit systems, such as radiators, underfloor heating, and central heating systems.

The pump components that come into contact with liquids are made of plastic and stainless materials to resist wear and corrosion from chemicals and debris. It features copper windings and thermal protection.

Pompedétartrage Lid and Filter

The machine’s lid and filter system are highly modern and user-friendly. With a diameter of 220 mm, the lid provides easy filling, draining, and observation. It can be easily opened and closed with a twist and includes a secure locking mechanism.

The basket filter system, uniquely patented for this machine, allows for visual monitoring of debris during operation, quick cleaning, and easy reinstallation.

Descalerpump Full Protection

The Pro-4 is so reliable that all its components come with a 2-year warranty. A liquid level control device prevents the heater from operating if there’s insufficient liquid, avoiding any potential damage. The machine's plastic body and chemical-resistant parts ensure long-term performance without wear.

Pressure Gauge (Manometer)

The pressure gauge monitors machine performance and blockage in the system. Lower pressure indicates effective cleaning with ample water circulation, while higher pressure signals blockages that need clearing. The machine adjusts pressure automatically based on system resistance.

Temperature Gauge (Thermometer)

The built-in thermometer lets you monitor and adjust the circulating liquid's temperature. Positioned for protection against tipping or impact, the gauge ensures durability during use.

Product Advantages

- Exceptional cleaning performance with 4 bar pressure and 60 L/min flow rate.

- No clogging issues in the pump, even after extended idle periods.

- Large, secure, and easy-to-use lid for effortless filling and debris monitoring.

- Ergonomic design for easy use, adding professionalism to your work.

- Durable pumps with copper windings and thermal protection.

- 100% domestic production with continuous spare part availability.

- 2-year company warranty.

Applications

- Combi boilers and condensing systems (compatible with all brands/models)

- Aluminum, cast iron, and panel radiators

- Iron, copper, and plastic pipes

- Underfloor heating systems

- Car radiator cleaning

- Cleaning of closed-circuit systems

Delivery Scope

- Kampa Pro-4 Radiator Cleaning Machine

- 2 x 2-meter flow and return hoses

- 1 x 2.5-meter discharge hose

- 1 x Basket Filter

- 2 x Wheels

Dual-Direction Reverse Cleaning

With dual-direction functionality, the machine cleans efficiently in both directions, preventing debris from settling in one spot. Reverse cleaning improves cleaning efficiency by 26% compared to single-direction systems.

Heating Element

The 2000-Watt heater ensures the cleaning liquid remains warm throughout the process, enhancing the effectiveness of chemical cleaning. The heater is equipped with a dry-operation protection feature, ensuring safety and reliability.

Note: High-pressure machines available in the market are unsuitable for pipeline cleaning as they can damage heating systems. The Pro-4 uses optimal pressure for safe and effective cleaning. Always use reliable chemicals for the best results and to avoid system damage.