MAGNET PUMP

Magnet Pump MD 15 R Magnetic Pump Single Phase (220 V) Chemical and Acid Pump

Magnetic Pumps: Overview and Key Features

Magnetic pumps are specifically designed for handling toxic and hazardous liquids without mechanical seals, reducing the risk of leaks and overheating due to blockages. These pumps operate using magnetic force rather than traditional seals or external electricity, making them energy-efficient and eliminating the need for seals or grease seals. They are suitable for a variety of liquids, including acids, water, and oils.

General Characteristics of Magnetic Pumps

Magnetic pumps contain a rotating impeller enclosed in a casing supported by a magnetic field. This configuration allows fluid to move through the casing, with the primary purpose of maintaining energy and movement within the fluid. Equipped with magnets on both the impeller and motor, the pump uses permanent magnets attached to the drive mechanism, which is connected to a second shaft driven by the motor. When the motor activates, it rotates the magnets, creating a magnetic force that turns the impeller and facilitates fluid movement.

- Pump Body: GFRPP Polypropylene

- Impeller Material: GFRPP Polypropylene

- Dimensions (DxHxW mm): 95x115x179

Operation Information

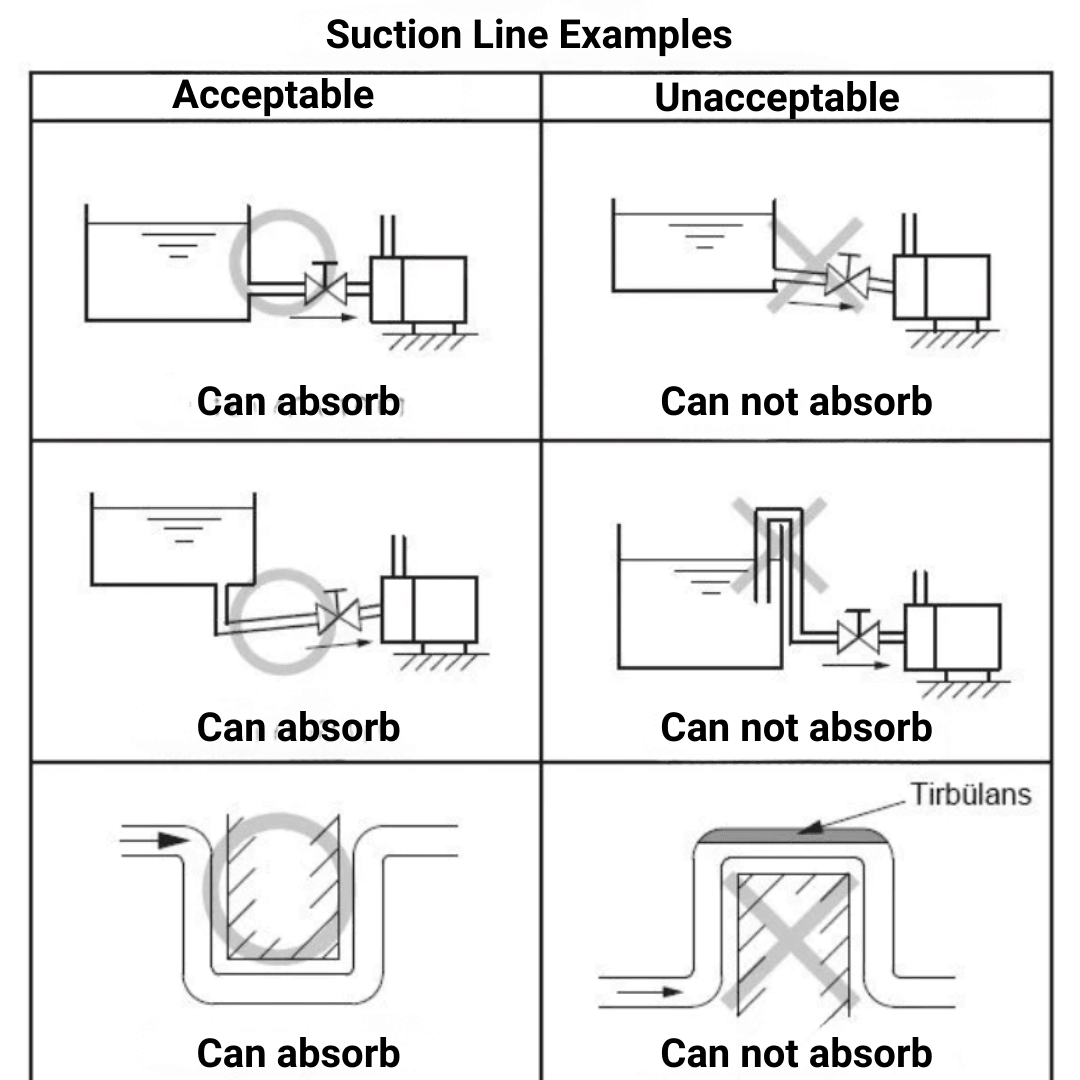

Magnetic pumps lack suction capabilities and rely solely on flow without generating a vacuum.

Voltage | Frequency | Max Flow Rate | Max Head | Inlet | Power |

220~240V | 50 / 60Hz | 16-19 l/min | 2.7-3.4 m | 14 mm | 35 W |

Polypropylene Material Properties

Polypropylene provides good resistance to acids and is suitable for food, chemical, and cosmetic applications. It operates effectively in temperatures ranging from 0˚C to 82˚C.

Compatible Fluids

The polypropylene body of magnetic pumps is suitable for the following fluids:

Fluid | Pump Body |

Milk | Polypropylene |

Aluminum sulfate | Polypropylene |

Liquid fertilizer | Polypropylene |

Phosphoric acid (10-20%) | Polypropylene |

Nitric acid (10-25%) | Polypropylene |

Parafin | Polypropylene |

Cyanide wastewater | Polypropylene |

Magnetic pumps are an efficient and safe solution for handling hazardous liquids, especially in industries that prioritize chemical and industrial applications.